Wir übersetzen Visionen in Lebensräume

Nur an unseren Taten werden wir gemessen. Mit dieser Überzeugung führen wir unser Unternehmen: Wer Mehrwert bietet oder eben mehr Wert bietet, muss definieren, was das heisst und danach wirtschaften und leben. Auf zwei Pfeilern stützen wir unser Unternehmen und unterstreichen damit, worauf wir bauen, um diesen echten Mehrwert für unsere Kunden zu erreichen:

Nachhaltigkeit und Innovation

Traditionelles Bauen war früher selbstverständlich nachhaltig. Heute ist nachhaltiges Bauen ein gesellschaftlicher Anspruch und eine Entscheidung für die Zukunft. Das Herzstück und Lebensader unseres Unternehmens ist Innovation. Sich stets weiterzuentwickeln, die Gegebenheiten der Gegenwart aufzunehmen und diejenigen der Zukunft zu antizipieren, ist Teil unserer Leidenschaft und das, was Sie von uns erwarten dürfen.

Ziegelpresse

Viele Jahre hat uns die Ziegelpresse in Zeitungsformat begleitet und unsere Kunden, Partner, Mitarbeitende und Freunde des Hauses über unser Tun informiert. Analog und ein- bis zweimal jährlich. Nun wollen wir Ihnen etwas regelmässiger einen Einblick über die Vielfalt unseres Schaffens gewähren: Willkommen auf unserer Ziegelpresse online!

zur Artikelübersicht

Die Themen Arbeit und Migration haben Winterthur gross gemacht, sind prägend in dieser Stadt, der Schweiz und nicht zuletzt auch Teil unserer Unternehmensgeschichte. Die Ausstellung im Museum Schaffen lädt ein, sich der Winterthurer Migrationsgeschichte aus neuer Perspektive zu nähern.

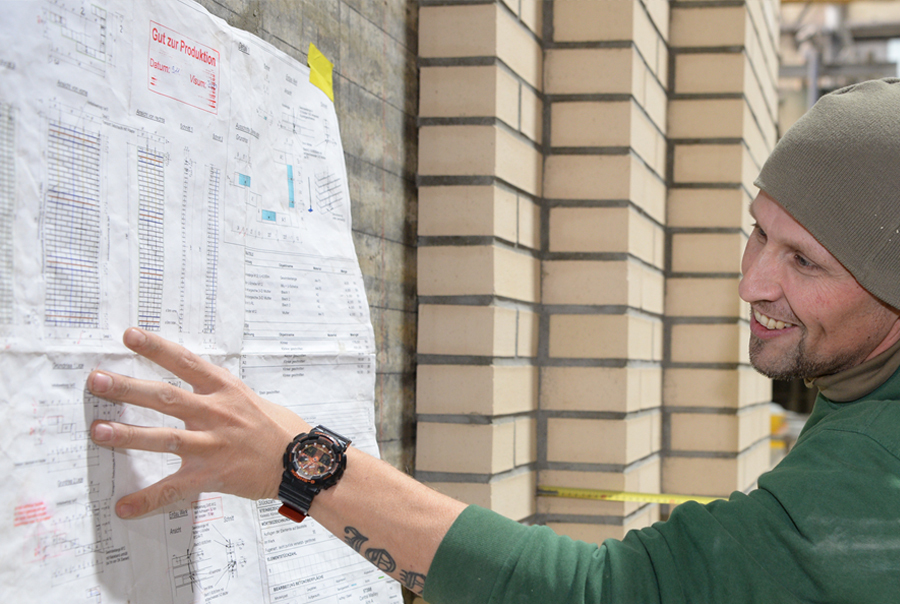

Heute wagen wir einen Blick hinter die Kulissen des Vorfabrikationswerk Pfungen. Produktionsleiter Matthias Janka nimmt uns mit und zeigt uns, wie ein vorfabriziertes Fassadenelement entsteht, welche Vorteile es bietet, und warum wir überzeugt sind, unseren Kunden ein wertvolles Produkt anzubieten.

Calma heisst unser neuestes Produkt aus der Raum-in-Raum-System-Familie, das wir seit unserem Büroumbau in Pfungen im Dauereinsatz haben. Da das Hauptaugenmerk des Umbaus auf der Verbesserung der Akustik lag, ist es an der Zeit, Bilanz zu ziehen.

Das Neueste aus unserem Instagram Feed.